Electric motor maintenance involves learning about the different parts and how they contribute to the motor’s function. Here, learn about commutators and what makes them essential to electric motors. You’ll learn what problems commutators can experience to help you recognize warning signs quickly.

What Should I Know About Commutators?

Commutators Defined

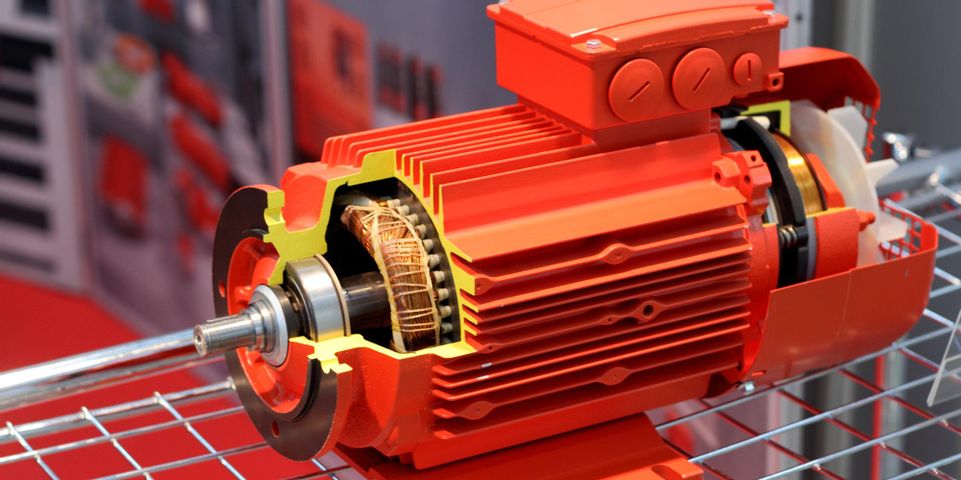

A type of rotary electrical switch, a commutator changes the current direction as necessary between the motor’s rotor and its external circuit. It features contact bars attached to the motor’s rotating shaft while also linking to its armature windings. The part makes certain the armature—a type of electromagnet—continually winds in the same direction by switching the flow of current when it’s needed to create consistent torque or rotational force. It converts AC currents into DC currents and vice versa to keep electrons flowing in the right direction.

Commutators work in tandem with brushes to allow current to flow to the armature. And because commutator contacts connect to the armature’s axle, they spin with the electromagnet.

Commutators work in tandem with brushes to allow current to flow to the armature. And because commutator contacts connect to the armature’s axle, they spin with the electromagnet.

Common Problems

Since electric motor brushes must stay flat and in complete contact with the commutator to transmit electrical currents effectively, brush maintenance keeps the part functional. Inspect the brushes regularly and look for signs of wear, including chips and cracks. Also, check that the brush is shiny and smooth, conforms entirely to the commutator and that the brush pigtail hasn’t sustained damage and remains attached to the brush. Have the brush replaced if you notice any of these problems.

Electric motor maintenance tips regarding the commutator also include checking the part’s bars. Gently tap the commutator with a small mallet or hammer to see if the bars have loosened and therefore vibrate or make odd noises. Loose bars emit dull thudding noises when they get hit, while secure bars produce pecking sounds.

Other tips include inspecting the commutator for dirt. While you do not want to remove the brown film where the commutator connects with the brushes because it keeps the part lubricated, wipe off any dirt and debris with a canvas rag to avoid malfunctions.

Schedule electric motor maintenance with United Electric Motors to keep the commutator and other parts functional. Based in Anchorage, AK, and serving the surrounding area for over 20 years, this renowned company provides 24/7 emergency repairs in addition to standard electric motor and generator services. Call (907) 563-5232 today to make an appointment or learn more about their services online. Like the Facebook page for additional tips.

About the Business

Have a question? Ask the experts!

Send your question