Precision grinding allows skilled fabricators to create a wide range of replacement parts and other items to the most exacting standards possible. Depending on the design and application of your product, a fabricator can use a variety of techniques and equipment to deliver the precision you need. Below are just a few types of precision grinding experts have at their disposal.

What Are the Common Types of Precision Grinding?

1. Surface Grinding

The grinding process works by applying an abrasive grinding wheel to the flat surface of the object. In surface grinding, a magnetic chuck holds the material being ground in place, while the abrasive grinding wheel is rotated over the top of the flat surface.

Movements can be manually controlled or CNC controlled by a computer program, which can yield incredible precision within less than one-thousandths of an inch.

2. Cylindrical Grinding

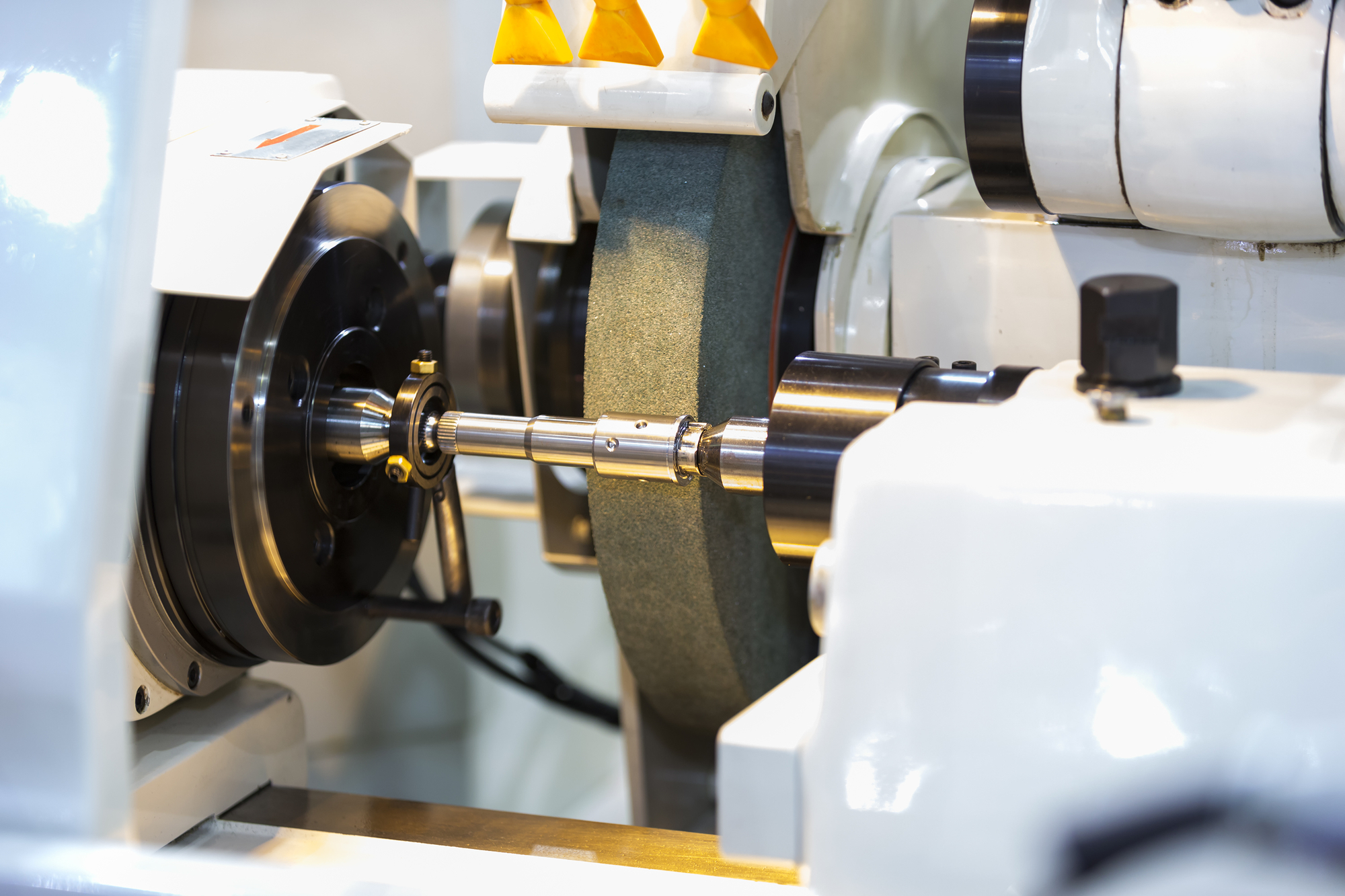

In surface grinding, the workpiece is held still while the wheel and tool are rotated at high speeds. Cylindrical grinding is accomplished by rotating the part to shape the outside of the item when uniformity and symmetry are essential.

In surface grinding, the workpiece is held still while the wheel and tool are rotated at high speeds. Cylindrical grinding is accomplished by rotating the part to shape the outside of the item when uniformity and symmetry are essential.

These machines rotate the product on a central axis, while the tool and workspace turn in the opposite direction. This technique is often used to create hydraulic pistons, airplane parts, and other components that must be perfectly straight and uniform.

3. Internal Grinding

Of the three techniques, internal grinding is the most complex, and it is used to create cylindrical profiles. A wheel grinder is mounted on a spindle or small shaft inside the bore of the part. The piece stays fixed as the wheel moves around it to grind the inside diameter. Several wheels may be used to shape the inside of the piece.

Internal grinding has many applications, including pipes, tubes, bushings, and parts for aerospace and industrial machine companies.

Since 1946, R.A. Heller Co. has been the precision grinding specialist of choice for businesses throughout the Cincinnati, OH, area. Their workshop features an array of the most advanced equipment in the industry, giving them the capacity to handle even the most difficult jobs. Visit their website for more on their wide range of precision grinding services, get tips and advice on Twitter, or call (513) 771-6100 to discuss your project with a member of their team.

About the Business

Have a question? Ask the experts!

Send your question