3 Facts You Should Know About Centerless Grinding

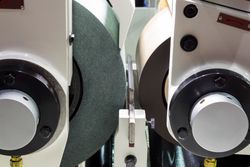

In machining, centerless grinding is a process in which material is removed from a workpiece with an abrasive wheel. But unlike other types of OD grinding, the workpiece is not held in place by a fixture or driver but by two wheels. One is the grinding wheel, which moves at a faster speed, while the other is a regulating wheel, which moves slower. Below, discover some important facts and benefits of this common machining technique.

What You Need to Know About Centerless Grinding

1. It Offers a High Level of Precision

The machinist can determine the speed of the two wheels used in centerless grinding, and they can place the regulating wheel in the best position for the most precise movement.

This results in a high level of accuracy and more control over the process and what the finished product looks like. Centerless grinding produces smoother finishes, straighter lines, and tighter tolerances than other kinds of OD grinding.

2. It Provides Greater Stability

The regulating wheel supplies consistent and dependable support to the workpiece throughout the grinding. While this stability is necessary for any sized project, it is particularly beneficial for longer workpieces with small diameters.

The regulating wheel supplies consistent and dependable support to the workpiece throughout the grinding. While this stability is necessary for any sized project, it is particularly beneficial for longer workpieces with small diameters.

The machining professional can perform a rough, intense grinding without fear that the workpiece will bend or suffer torsional stress. The strong grinding action will cause no damaging distortions because of the solid stability of the regulating wheel.

3. It Saves Time & Money

Productivity is markedly increased with a centerless grinder. Parts are loaded into the machine automatically, and smaller pieces can be loaded in large quantities, meaning less downtime and a smooth workflow.

This approach also means lower labor costs. The grinder itself is very low maintenance as well, requiring little upkeep or special care after the initial setup—another undeniable money-saver.

When you need centerless grinding in the Cincinnati, OH, area, contact R.A. Heller Co. Since 1946, they have been providing machining services to business and industrial customers. From centerless grinding to hard chrome plating, from horizontal boring to piston rod repair, they are your one-stop machining resource. They will gladly tackle any job, large or small. Call (513) 771-6100 or visit them online to request an estimate.

About the Business

Have a question? Ask the experts!

Send your question