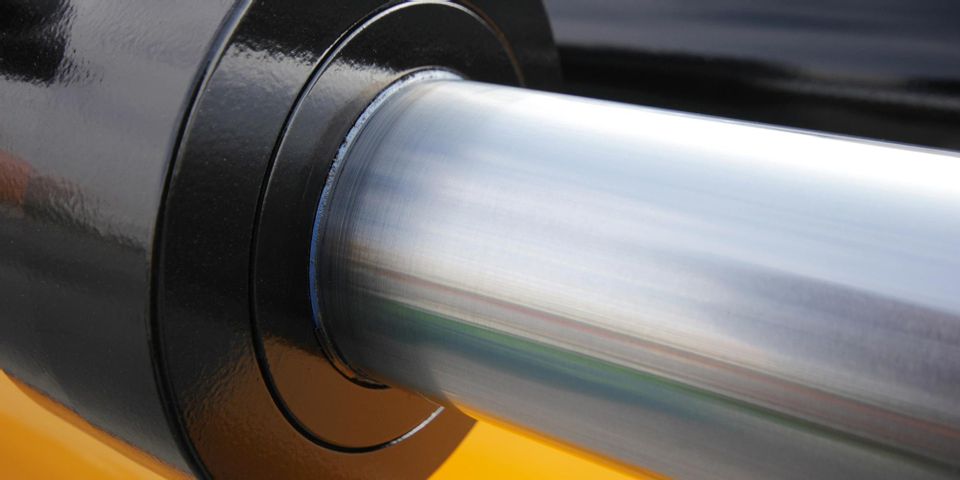

One of the most common components in heavy machinery is the hydraulic cylinder. A hydraulic cylinder depends on several components remaining well-aligned, adequately lubricated, and resistant to heat, pressure, and corrosion. With that in mind, several factors can lead to hydraulic cylinder failure, requiring cylinder repair and putting equipment out of commission for some time. Here is a list of five common causes of hydraulic cylinder failure.

Common Causes of Hydraulic Cylinder Failure

1. Seal Breach

Damaged seals are one of the most common causes of hydraulic cylinders to lose operational pressure. Seals can be damaged by physical trauma, age, or coming into contact with corrosive chemicals. In any case, when a seal goes bad, the hydraulic system will begin to experience increased performance degradation as less pressure is maintained in the cylinder.

2. Contaminated Fluid

Another common cause is running a hydraulic cylinder with contaminated fluid. If foreign particulates are introduced to the hydraulic fluid, they can damage the inside of the cylinder, the seals, and the fittings. The added friction and potential corrosion inside the cylinder will degrade the functionality of the whole system and can cause a catastrophic failure if the cylinder is under excessive pressure.

3. Broken Eye Bearing

If the cylinder is being pushed beyond its load specifications, the chance of failure increases exponentially. When this type of treatment is repeated, the cylinder will ultimately fail, and that often starts with the eye bearings, which are a type of spherical, rotating joint and often the weakest point of a hydraulic system’s moving parts.

If the cylinder is being pushed beyond its load specifications, the chance of failure increases exponentially. When this type of treatment is repeated, the cylinder will ultimately fail, and that often starts with the eye bearings, which are a type of spherical, rotating joint and often the weakest point of a hydraulic system’s moving parts.

4. Side Loading Strain

Since hydraulic cylinders are designed to operate in one direction, any pressure that is working perpendicularly against the cylinder can cause the rod to bend or put too much pressure against the shaft’s fasteners. Operating with a damaged cylinder rod can result in a catastrophic failure. Cylinder repair may require replacement of the entire rod if it becomes deformed.

5. Extreme Temperatures

An inadvertent case of hydraulic cylinder failure comes from exposure to extreme temperatures. This affects two key elements: hydraulic fluid and cylinder seals. The fluid may not have the proper viscosity to function at certain temperatures, being too thick and causing too much pressure on the system when operating in extreme cold or generating too much heat in the cylinder when operating in extreme heat. The seal materials may also crack and break apart from radical temperature shifts.

If you have equipment that requires hydraulic cylinder repair, you should contact the experts at LWG Finishing in West Chester, OH. They’re specialists in repairing and coating hydraulic shafts for industrial, mining, and construction machinery and have served the area for over 50 years. Call them today at (513) 860-1156 or visit their website for more information.

About the Business

Have a question? Ask the experts!

Send your question