A progressive cavity pump is a device used in a variety of industrial settings. This innovative product is renowned for its efficiency, especially when dealing with more viscous substances that might not pass through conventional centrifugal pumps with ease. Here’s what you should know about this piece of equipment.

What Are Cavity Pumps?

Progressive cavity pumps are designed to displace fluid through positive action. As a positive displacement pump, this means that the device pulls the substance via suction, and it then makes its way through the pump as the rotor turns. When a thick liquid is introduced to the device, its mechanical efficiency improves, and it generates increased flow without consuming too much power. The opposite is true of a centrifugal pump, which has to work overtime to do its job when the substance is too thick. That’s why this pump is reliably used for viscous materials.

How Do They Work?

The progressive cavity pump is made with a rotor that spins within the pump. As it does that, small cavities remain in its wake. The fluid that you push through the pump sits within those cavities when the rotor moves. As they’re pushed through the system, the cavities retain their structure so that the liquid remains the same when it’s expelled from the pump.

The progressive cavity pump is made with a rotor that spins within the pump. As it does that, small cavities remain in its wake. The fluid that you push through the pump sits within those cavities when the rotor moves. As they’re pushed through the system, the cavities retain their structure so that the liquid remains the same when it’s expelled from the pump.

Why Are They Useful?

There are many reasons why you may require this type of pump. The most apparent advantage is its ability to safely and successfully handle materials of all viscosities, making it a more versatile choice that can be used across a variety of industries and applications.

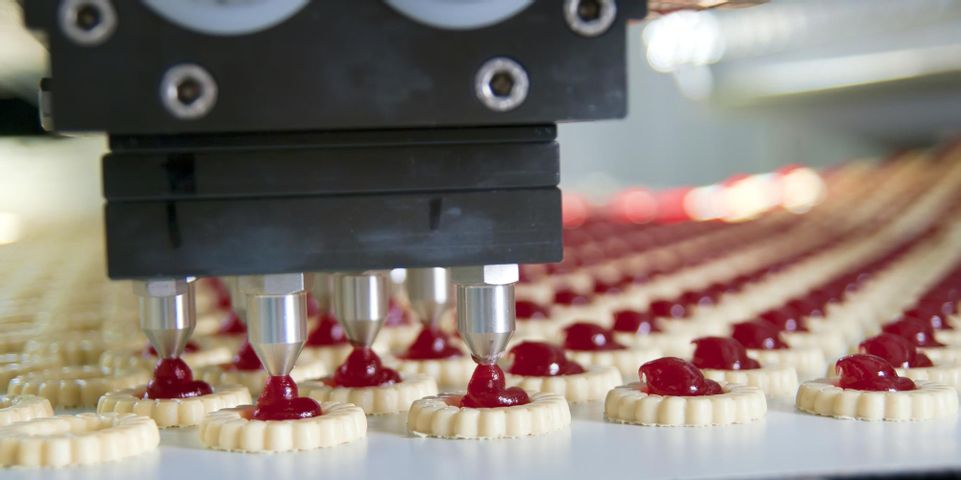

If you work in an industry where you need to supply an exact amount of a product accurately, this type of pump is essential. For example, it can place the precise amount of cream into a packaged pastry or the same amount of sauce onto a pizza, making it useful for food production companies. Additionally, the product is helpful for paper mills, waste treatment facilities, and companies with petroleum-based products.

Finally, the pump does not crush any products. Instead, materials move through it, which preserves their integrity from start to finish.

Clients throughout Cincinnati, OH, trust in the professionals at R.A. Heller Co. for their machining needs. Serving the area since 1946, this machine shop offers a variety of essential products and services, including the repair of progressive cavity pumps, chromium, hard chrome plating, and hydraulic repairs. Visit their website to find out more, or call (513) 771-6100 today to speak with an experienced representative.

About the Business

Have a question? Ask the experts!

Send your question