What Are Heat Exchangers and What Advantages Do They Offer?

Many types of equipment rely on heat exchangers to remain operational and effective. While these devices come in many varieties, they all serve the same purpose: to move heat from one area to another using the principles of thermodynamics. As such, they can be incredibly useful when used in HVAC equipment, air compressors, refrigeration equipment, manufacturing systems, and more. To shed more light on this essential component, here are five benefits that heat exchangers can offer.

5 Heat Exchanger Benefits

1. Versatile Design

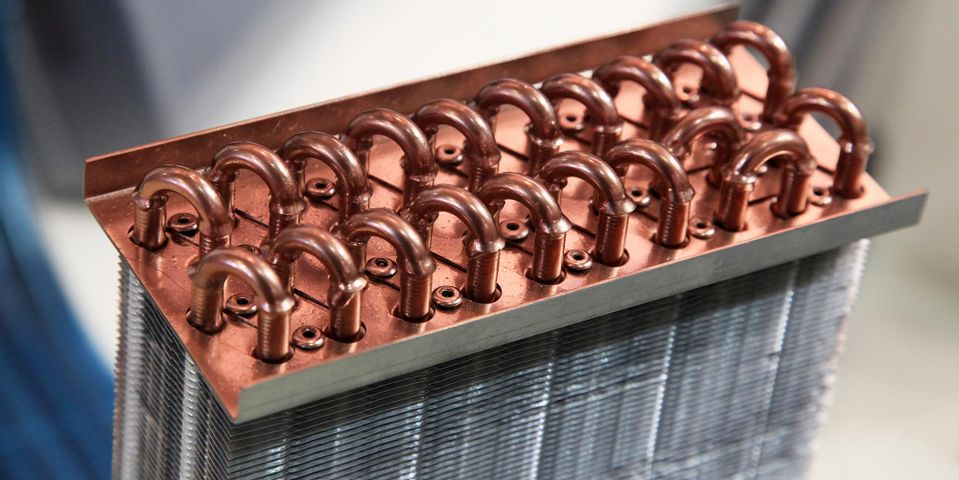

Heat exchangers consist of plates or tubes that are filled with a fluid or gas that can absorb and release heat. While early versions of this technology were large, today’s models are much more compact and versatile. For example, a plate heat exchanger is ideal for applications that require lighter parts. A tube-based system may be more appropriate for devices that have unique sizing requirements, as the tubes can be manipulated to fit different dimensions.

2. Improves Energy-Efficiency

Hot air that’s absorbed by a heat exchanger can be directed to other components that may need the resource. For example, this part can absorb heat from a car’s engine and direct it into the vehicle’s cabin to make the temperature more comfortable. Since the device isn’t using fuel or extra electricity to operate, it can save a lot of energy, which, in turn, can benefit budgets and the environment.

Hot air that’s absorbed by a heat exchanger can be directed to other components that may need the resource. For example, this part can absorb heat from a car’s engine and direct it into the vehicle’s cabin to make the temperature more comfortable. Since the device isn’t using fuel or extra electricity to operate, it can save a lot of energy, which, in turn, can benefit budgets and the environment.

3. Cuts Costs

In the past, heat exchangers would require welding and other costly manufacturing measures. Today, however, components are factory-pressed or molded to reduce production costs. Since these devices don’t need additional power to operate, they can also reduce fuel expenses.

4. Reduces Maintenance

Heat exchangers are fairly low maintenance and can provide a service life of up to 25 years. Typically, the device will only need to be cleaned occasionally to prevent debris from accumulating on surfaces—a problem that can impair performance. And if an exchanger goes bad, technicians can usually replace the part without having to dismantle other equipment that it’s attached to.

5. Removes Moisture

During the condensation process, heat exchangers remove moisture from the air so that it’s directed into a drainage system. When used in an HVAC system, these devices can help reduce humidity. And when they’re used as aftercoolers for air compressor motors, they prevent condensate from damaging the equipment.

While heat exchangers offer plenty of benefits over alternative systems, they still need to be well-designed to deliver consistent results. That’s why the Parts Engineering Company is dedicated to providing customers with a variety of high-quality OEM and aftermarket heat exchangers—such as those used for air compressors. Based in the St. Louis, MO, area, this specialist services customers throughout the country and provides convenient, 24/7 service to customers in the St. Louis area. To learn more about their expansive inventory of compressor parts, visit this supplier online. For compressor service requests, call (877) 797-7326.

About the Business

Have a question? Ask the experts!

Send your question