Hard chrome plating is a popular method of reinforcing mechanical components to boost performance and reduce costs. Through this method, metal parts bond with a layer of chromium through a process known as electroplating—or being placed in a bath that’s exposed to electric current. While this method is extremely versatile, the individual design of each product can influence the success of the plating results.

What Are the Benefits of Hard Chrome Plating?

1. Strength

Compared to other abrasive industrial metals, hard chrome is thicker and tougher. Its superior hardness makes it incredibly strong and durable—even when exposed to high-force and continuous stress. The plating is tough enough that it can also be used to restore metal parts that have worn down and grown weaker.

2. Corrosion Resistance

Hard chrome, especially paired with a nickel base, is extremely resistant to oxidation. As such, plated materials can stand up to wet conditions—such as those found in food processing plants—without the danger of corrosion.

3. Reduced Friction

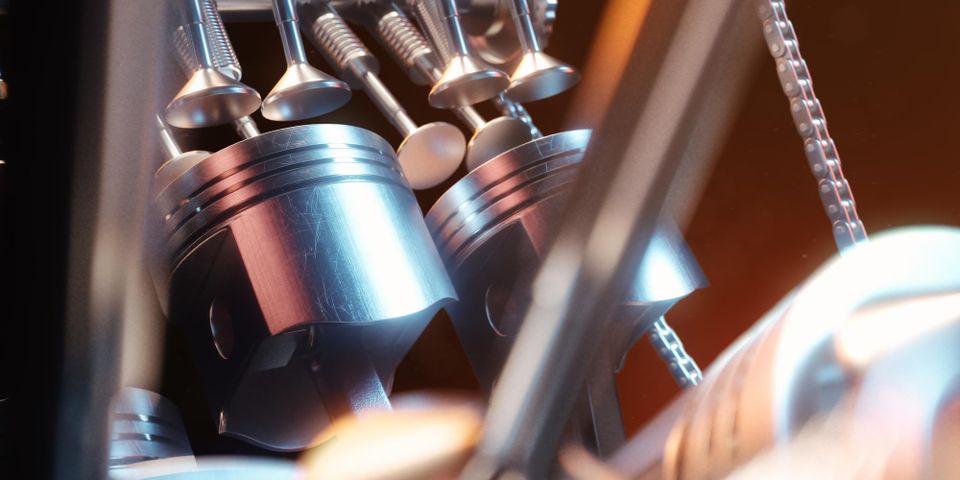

The low friction of hard chrome allows plated components to stand up to abrasive, metal-to-metal contact without generating heat. This advantage allows parts to move faster and avoid overheating.

The low friction of hard chrome allows plated components to stand up to abrasive, metal-to-metal contact without generating heat. This advantage allows parts to move faster and avoid overheating.

How Can Product Design Improve Hard Chrome Plating Results?

1. Round the Edges

If you’re preparing parts for plating, remember that sharp edges will experience a greater buildup of hard chrome. This occurs because when electricity passes through the bath, it flows in a straight line to the closest point of contact. To prevent edges from developing a disproportionate layer of plating, gently radius the edges at no less than 1/32 of an inch.

2. Shape the Corners

Similar to edges, 90-degree corners can also experience excessive chrome buildup. You can avoid this problem by reshaping the surfaces to create either a radius, shoulder, or undercut corner.

3. Adjust the Threads & Splines

Parts with threads and splines will collect more chrome along the raised tapered edges. Gently radius the sharp tips and bases, as well as reduce chrome thickness to create a smoother plate.

4. Check the Size

While any object can be plated, it must fit in the bath that holds the chrome solution. As such, you should make sure any items to be plated fit the dimensions of your machine shop’s tanks.

When you want to elevate the performance of your engineered machine parts, turn to R. A. Heller Co. in Cincinnati, OH. Serving industrial clients for more than seven decades, this shop is recognized for providing top-notch machining, grinding, and repair services to create durable, functional parts. They also offer versatile hard chrome plating to protect a wide range of components. To learn how this machine shop can improve your mechanical operations, visit their website or call (513) 771-6100.

About the Business

Have a question? Ask the experts!

Send your question