How Is Polyurethane Utilized in the Medical Industry?

Polyurethane is a plastic polymer that’s used in a wide variety of industrial and consumer products, including car parts, mattresses, shoe soles, and a variety of medical applications. Polyurethanes are superior to other materials in tear resistance, flexibility, and abrasion resistance. Here are some ways polyurethane is used in the medical industry.

5 Ways Polyurethane Is Used in the Medical Field

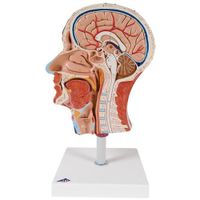

Polyurethanes are used in the making of many Medical Training models in the market today. Medical simulation is useful in education to build students competency in clinical skills and diagnostic procedures. Simulation training has proven effective in medical student training to demonstrate, practice and assess clinical skills. Here are some ways polyurethane is used in the medical industry.

1. Anatomy Models: realistic replicas used when teaching medical students about Human Anatomy and human cells. Anatomy models depict everything from microanatomy to full body systems. Human anatomy models are appropriate for teaching whether you need an assembled, dissected or partially dissected view.

2. Bone Models: mimic the properties of human bones and are an alternative testing media to a human cadaver bone. Bones are designed to be cut, drilled, tapped, or gouged with standard hand, or powered instruments for testing, comparing, or designing implants and other devices.

3. CPR manikins: designed to provide student training in CPR, AED use, and the Heimlich maneuver. Realistic anatomical markings (Adam's apple, carotid arteries, navel, rib cage, chest notch) make it easy to learn correct hand placement for checking pulse and performing chest compressions.

4. Surgical Simulators: anatomically correct human body forms allow students to practice a variety of advanced surgical procedures. When working with simulators, trainees can repeatedly practice techniques and manage complications until they achieve expertise in performing the simulated operation.

5. Suture Pads: allow users to practice suturing skills with lifelike tissue structure molded in various shapes and sizes. Users can make incisions and determine the depth of suturing and the technique to be used; practicing and demonstrating tying knots, stapling and placement of staples, use of surgical glue, suturing deep tissue, and suturing subcutaneous tissue.

If you’re looking for molds and casting supplies, turn to the professionals at BJB Enterprises in Tustin, CA. They have been in business since 1970 and offer polyurethane, silicone, and epoxy products. These professionals work with several industrial companies to manufacture unique and customized products, using 3D printing to make precise molds and castings. They’re ISO certified and go beyond the call of duty to provide their customers with quality products. For more information about their custom products, call (714) 734-8450 or visit their website.

About the Business

Have a question? Ask the experts!

Send your question