SD-WAN in the Manufacturing Industry

Manufacturing is one of the largest and fastest-growing sectors of the global economy. According to the National Association of Manufacturers, manufacturers contribute over $2 trillion a year to the economy in the US alone. The recent advancements in technology are offering a great number of benefits for manufacturers by helping enable real-time information, analysis and control to enhance efficiency across all departments of the manufacturing business. One of such technologies that are set to have a huge impact on manufacturing is SD-WAN or software-defined wide-area networks. Unfamiliar with SD-WAN? Keep reading to find out what SD-WAN is and how it is benefiting the manufacturing industry today!

What is SD-WAN in a Nutshell?

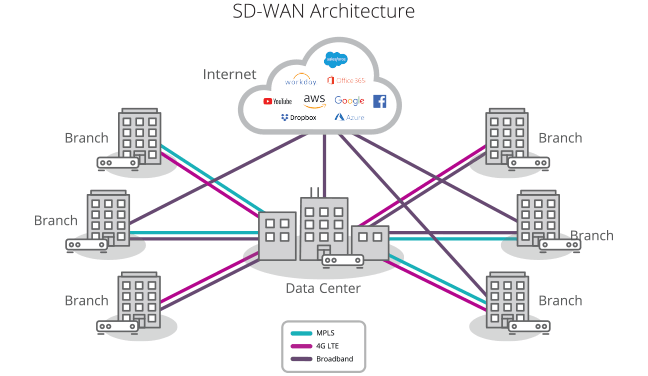

SD-WAN is the newest capability in the world of WAN. Software-defined networking capabilities can be applied as a virtual overlay to a company’s current WAN connection which would typically be MPLS-based today. Having SD-WAN can allow your business to connect your branches and data centers, optimizing network performance, for about a third of the cost of using solely MPLS. One good thing about SD-WAN is that, since it is software, the configuration of this solution onto your current infrastructure is quick and easy and can produce OPEX and CAPEX savings by up to 90 percent in a few short months. Reference

“The average cost of network downtime is around $5,600 p/minute, which extrapolates to just over $300K p/hour. A large financial impact for any organization”

- Gartner

How is SD-WAN Benefiting the Manufacturing Industry?

IoT Readiness: The Internet of Things has quickly become one of the most transformative technological innovations in recent memory. However, in order to fully realize the potential of the Internet of Things, manufacturers will need wide area networks that are capable and flexible enough to meet the demands of the not-so-distant future. With the growth in the Internet of Things estimated to bring over 50 million connected devices by the year 2020, typical WAN networks will almost inevitably struggle to keep up with growing demand. This is where software-defined wide area networks (SD-WAN) come into play. SD-WAN is currently able to provide network administrators with enhanced new levels of network visibility with which to manage these new endpoints as well as actively prioritize the traffic of critical IoT devices to ensure the best possible network route.

Connectivity: As wireless communication technologies and IoT devices improve over time, connectivity will become an increasingly important part of SD-WAN within the manufacturing industry. Connectivity is also important for ensuring that a range of WAN links such as 4G LTE and 5G are supported, particularly for use in remote, traditionally hard to reach locations. This is another way in which SD-WAN enables manufacturers to fully take advantage of the benefits of connected IoT devices. With autonomous vehicles also lingering on the horizon, the ability to host multiple WAN links will likely become an increasingly essential function of SD WAN within manufacturing by the time driverless vehicles do eventually begin to be rolled out.

Security: SD-WAN is providing enhanced security solutions for traditional network issues by delivering an unprecedented level of visibility into network activities at individual WAN sites, the corporate data center, or cloud environments. SD-WAN is also able to ensure that all individual traffic is encrypted against unauthorized access and can be centrally managed, so as to extend a manufacturers security perimeter while also enabling remote locations to be included within as well, without the extra costs. The added security functionality that SD-WAN’s come with is likely to drive further development of software-defined networking technologies utilizing some type of security-by-design template. The deluge of data that IoT devices generate will become a big target for malicious hackers looking to steal proprietary or personal data and so manufacturers will need to ensure that, not only is their SD-WAN suitable for deployment in their environment but also that adequate security measures are included or put in place. Reference

Manufacturing Case Study: A rapidly expanding distributor of construction products was faced with an aging PBX system and the need to add additional locations that needed to be supported by their HQ based ERP platform. The platform is latency sensitive and was a factor in the network connectivity design for the new remote offices.

CDP delivered a hosted VoIP solution with UCaaS coupled with SD-WAN to provide seamless communications between the new branches, mobile workforce and corporate. SD-WAN between the sites allowed for network resiliency, lower latency, and real-time network/application performance statistics.

Contact Communications Deployment Partners today for help getting SD-WAN right in your own terms! 215.343.5580 or solutions@cdpartnersllc.com

About the Business

Have a question? Ask the experts!

Send your question