How to Choose Between Nickel & Hard Chrome Plating

Plating an object is the process of altering its surface to improve its appearance, corrosive properties, and durability. Chrome plating and nickel plating are the most common industrial plating processes, and each has its own advantages. This guide explains the processes and benefits of both types of plating

Plating Methods Explained

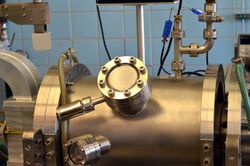

Electroplating

For electroplating, an object is dipped into an electrolyte bath that contains chromium or nickel ions. When an electrical charge is applied to the bath, the ions magnetically adhere to the object in a perfect, evenly-distributed coating. The thickness of the coating can be altered by changing the amperage applied, and the length of time the object is left in the bath.

Electroless Plating

This process is similar to electroplating, but instead of using electricity as a bonding agent, it relies on an autocatalytic reaction where a single chemical reaction is created. Metal ions, reducing agents, complexing agents, and a bath stabilizer are used, and with the correct heat and pH ranges, a catalytic substance, such as nickel, can be dipped into the bath to plate over the object.

This process is similar to electroplating, but instead of using electricity as a bonding agent, it relies on an autocatalytic reaction where a single chemical reaction is created. Metal ions, reducing agents, complexing agents, and a bath stabilizer are used, and with the correct heat and pH ranges, a catalytic substance, such as nickel, can be dipped into the bath to plate over the object.

The Advantages of Hard-Chrome & Nickel Plating

Hard-Chrome Plating

Chromium is ideal for parts that constantly grind or rub against other parts. Chromium reduces friction, promotes sliding between components, and in some cases, is harder than the material it’s applied to — which increases the part’s durability.

Nickel Plating

In most cases, electroless nickel plating is ideal for large unfinished parts because of its dependability and versatility. It’s softer than chrome, but its evenly dispersed layering is very smooth and often doesn’t require grinding after plating. It improves corrosion and wear resistance of an object, and is best for complex parts. Chrome can be applied over a nickel coating to maximize its resistance to corrosion and wear.

Delivering superior products in Cincinnati, OH, Northern Kentucky, and Indiana, Porter-Guertin Co. provides all of your chrome plating and nickel plating needs. They use advanced technological procedures to increase the durability and reliability of their clients’ metal parts, and their team will find and implement a solution that will maximize the performance of your components. To learn more about what this company can do for you, call (513) 241-7663 or reach out online to learn more about their nickel and chrome plating services.

About the Business

Have a question? Ask the experts!

Send your question