When you’re aiming to have metal products produced on your behalf, it’s important to work with a company that has the necessary equipment to get the job done precisely. A staple of a quality machine shop is the CNC machine (computer numeric control), which links a computer and a powerful tool to shape metal products. Here are four of the most useful variants of the machine you should be aware of.

A Rundown of CNC Machines

1. CNC Mills

This type of CNC machine enables the cutting of a piece of metal in a highly precise manner. Instead of relying on a human hand, the tool removes the designated amount down to the last micrometer. The device has the flexibility to vary both the angle and depth of its cuts.

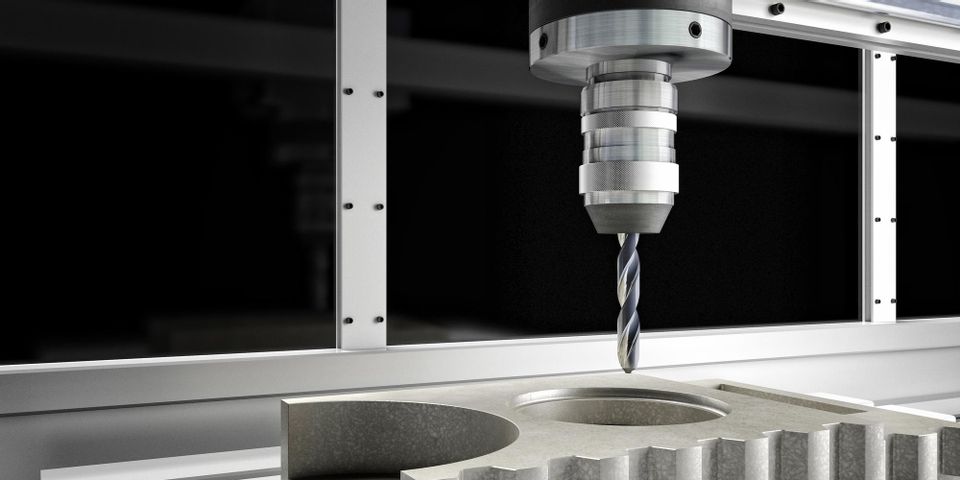

2. CNC Drills

These machines are useful when you need to create holes in your metal. Not only will it be the right size, but you can place the hole in an identical spot on each new product.

These machines are useful when you need to create holes in your metal. Not only will it be the right size, but you can place the hole in an identical spot on each new product.

3. CNC Lathes

The CNC lathe also serves a cutting function but adds the additional facet of turning the piece. That rotation is perfect when you’re working with curved objects that may take a spherical form.

4. CNC Plasma Cutter

For cutting through more substantial metals, you may need to use a CNC plasma cutter. The technology transforms gas into extremely hot plasma, which can easily slice metals like steel.

If you’re in need of high-quality metal work, reach out to the reliable machine shop, C & C Machine. Thanks to their CNC machines, they can deliver metal products to your exact specifications. The shop’s technicians have a wealth of experience operating the computer as though it were an extension of themselves. You can receive a consultation with their staff by calling (608) 784-4427. Learn more about the shop by visiting their website.

About the Business

Have a question? Ask the experts!

Send your question