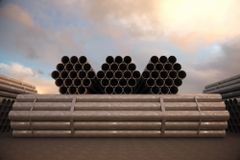

Metal piping is the safest way to facilitate water and gas flow throughout a property. When purchasing from a metal fabrication company, you need to make sure you choose the right material—galvanized or black piping—for the intended purpose. Here’s a breakdown of the two options.

Black Piping

After a metal fabrication company forges steel, black oxide will settle on the surface, which is how black piping earns its name. Because it’s manufactured without seams, it’s less likely to leak, making it suitable for gas travel. It’s also fire and heat-resistant, so it lowers the risk of combustion and gas leak-related fires. These reliable qualities have made black piping required for gas lines throughout the country.

Black piping is most commonly used to route propane and natural gas throughout properties as well as connect appliances to gas and drain lines. However, it’s susceptible to rust, so it shouldn’t be used for water transport.

Galvanized Piping

Water will wear down metal and lead to corrosion. The resulting leaks can create costly water damage. To prevent corrosion, galvanized piping is used in plumbing systems. After metal fabrication, the steel piping is coated with zinc, which is naturally corrosion-resistant.

Water will wear down metal and lead to corrosion. The resulting leaks can create costly water damage. To prevent corrosion, galvanized piping is used in plumbing systems. After metal fabrication, the steel piping is coated with zinc, which is naturally corrosion-resistant.

However, zinc does pose some risks. It tends to flake off and can even build up to the point of obstructing a pipe’s flow, resulting in ruptures. Galvanized pipes may also contain lead, so they can’t be used to transport drinking water. Outside of gas transport, galvanized piping is used for scaffolding, sewage plumbing, and agriculture.

If you need black or galvanized piping work for an upcoming construction project, the professionals at Incom are here to help. This Kailua-Kona, HI-based company brings over 40 years of experience as a one-stop shop for metal fabrication and comprehensive welding services, including mobile onsite welding. Call (808) 329-1311 to request a free estimate, and learn more about their services online.

About the Business

(6 reviews)

Have a question? Ask the experts!

Send your question