As modern technology advances, the process of producing products and parts is growing more and more automated. One manifestation of this trend is CNC machining, which allows for computer-controlled design and manufacturing of custom plastic parts and other materials. Here is what you should know about this process.

What Does CNC Mean?

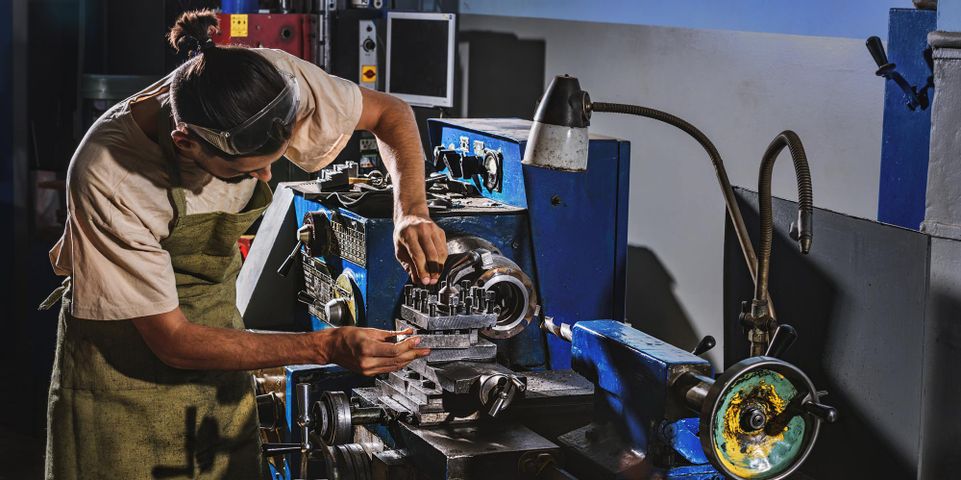

CNC stands for "computer numerical control," and refers to the computer system used to operate the machinery. In some ways, CNC machining is similar to 3D printing technology, but unlike a 3D printer which builds up the custom plastic object, CNC systems cut or mill it out of blocks of material such as wood, metal, foam, fiberglass, or plastic. Regardless of the material, the system relies on programmed instructions which tell it where, in what direction, and how far to cut. Tools which can be controlled in this way include drills, lathes, plasma cutters, water jets, and other more unusual ways of cutting and shaping material.

CNC stands for "computer numerical control," and refers to the computer system used to operate the machinery. In some ways, CNC machining is similar to 3D printing technology, but unlike a 3D printer which builds up the custom plastic object, CNC systems cut or mill it out of blocks of material such as wood, metal, foam, fiberglass, or plastic. Regardless of the material, the system relies on programmed instructions which tell it where, in what direction, and how far to cut. Tools which can be controlled in this way include drills, lathes, plasma cutters, water jets, and other more unusual ways of cutting and shaping material.

What are the Benefits of This Machinery?

One of the biggest reasons to rely on CNC machining is the control and precision of the system. A person operating the same tools produces less reliable, uniform results. However, CNC provides precise and effective results at a faster rate. It even has some advantages compared to 3D printing. While printing is better at creating complex shapes, CNC machining can produce not just custom plastic components, but also a wide range of materials like wood, which a 3D printer can't use.

If you're looking for custom plastic products and parts, choose Faro Industries in Rochester, NY. With over 50 years in the fabrication industry, they have developed a reputation for quick turnaround times and quality products. They offer both 3D printing and CNC machining for the greatest versatility in production. To discuss your project, call (585) 647-6000 or visit their website to learn more about their offerings.

About the Business

Have a question? Ask the experts!

Send your question