What You Should Know About V-Belts

Almost any piece of equipment, from the largest industrial conveyor system to a normal passenger vehicle, needs to transfer power from the motor to gears or pulleys. V-belts are commonly used in agricultural and industrial machinery because they transmit power in high-torque situations, are reliable and easy to repair and replace. To accommodate a variety of needs, manufacturers offer an array of designs, each with unique properties making them ideal for different applications.

A Brief Guide to V-Belts

What Is a V-Belt?

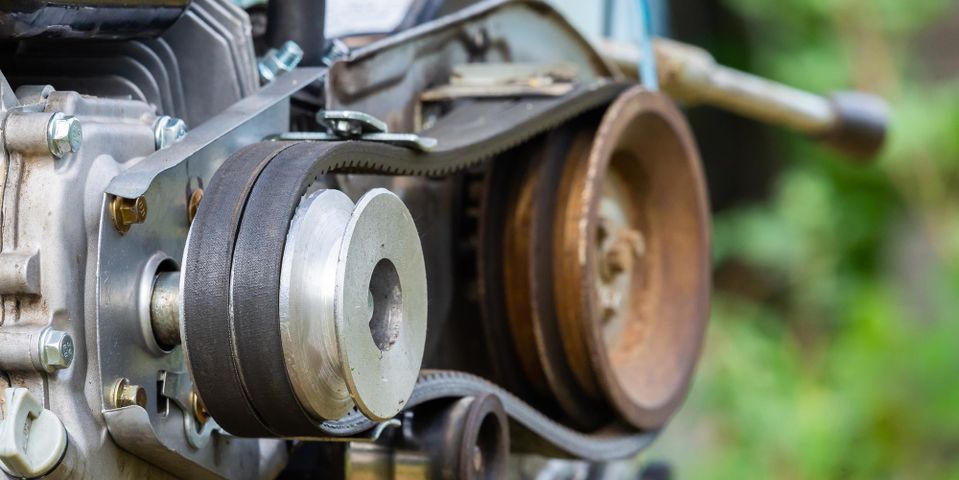

V-belts are power transmission devices that are wider on one side than the top, creating a trapezoidal cross-section that looks somewhat like the letter “V.” These belts are designed to fit into channels on pulleys that are narrower at the bottom than at the top, creating a stronger grip and maximizing the total amount of surface friction.

How Does This Equipment Benefit Me?

Because they fit inside a groove on the pulley, V-belts can’t slide off under high tension, a common problem with other designs. As the load on the belt increases, it will also wedge deeper into the guiding groove, increasing the transmission of torque under conditions in which other devices might fail.

Because they fit inside a groove on the pulley, V-belts can’t slide off under high tension, a common problem with other designs. As the load on the belt increases, it will also wedge deeper into the guiding groove, increasing the transmission of torque under conditions in which other devices might fail.

Are There Different Types of V-Belts?

Classic wrapped or cut edge cogged V-belts are often used in agricultural and industrial operations to power conveyors and other material handling equipment. If power transmission is needed in both directions, a common requirement in textile production, manufacturers may use a double V-belt, which has a hexagonal cross-section capable of grabbing pulleys on both sides. When multiple belts are required, a banded belt made of several V-belts joined together can provide superior power transmission and prevent tangles and individual belt elongation. This style is often used in high-impact environments or on load-carrying equipment due to its strength. Common industries are Aggregate, Agricultural and Oil and Gas.

For nearly 20 years, Industrial Components Sales, Inc. (ICS) of Hudson, WI, with offices in Bemidji, MN, Delavan, WI and Lincoln, NE, has provided power transmission sales, service, and expertise to businesses throughout the Midwest. With their in-depth understanding of a variety of industries, representation of high-quality products and strong relationships in the Midwest, they have the knowledge to keep your operation running efficiently. Visit their website for more on Bestorq V-belts, MasterDrive sheaves and bushings or a variety of other industrial products ICS represents, or call (651) 270-0151 to discuss your needs with a certified professional today.

About the Business

Have a question? Ask the experts!

Send your question