How to Figure Out Why Your Gears Fail

Gears are among the most important power transmission products in a wide range of vehicles and industrial machinery, and the unexpected failure of even one can bring your operations to a halt. While having a reliable supplier of replacement parts will get you up and running again, understanding why your gears failed can help you avoid breakdowns in the first place. A careful examination of your failed gears can help you pinpoint the problem, potentially saving thousands in extra maintenance and avoidable repairs.

What’s Causing Your Gears to Fail?

Understanding Different Types of Damage

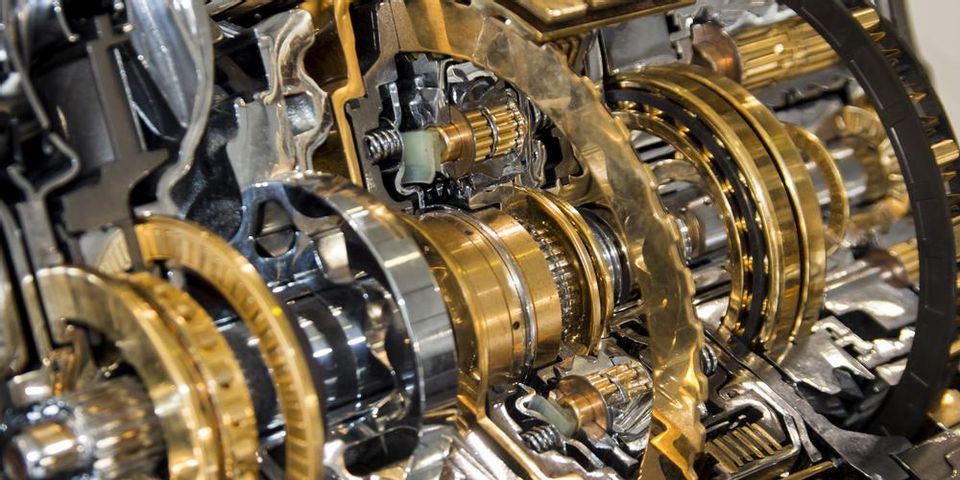

Most power transmission product failures are caused by damage to the surface of the gear or breakage of the teeth. In some cases, deterioration of plastic components or other problems with the gearbox itself might be to blame.

Most power transmission product failures are caused by damage to the surface of the gear or breakage of the teeth. In some cases, deterioration of plastic components or other problems with the gearbox itself might be to blame.

Gear Tooth Surface Damage

Surface damage on the teeth of the gear can be traced to a variety of issues, from inadequate lubrication to a harsh startup. If enough of the surface wears away, the tooth won’t mesh properly with the other gears, resulting in power loss and extra vibrations. Some wear is caused by old age, but more often it indicates that the gear is being subjected to too much force.

Broken Teeth

Gear teeth that are routinely placed under more stress than they were designed to handle may weaken and break off, which could render the entire gear inoperable. In many cases, addressing this issue may require new power transmission products designed to withstand the force of your application.

Industrial Components Sales of Hudson, WI, provides the best power transmission products in the industry to manufacturers throughout the Midwest with offices in Bemidji, MN, Delavan, WI and Lincoln, NE. Their staff has over 40 years of combined experience, giving them the expertise to help you choose the ideal components for your machinery. To get in touch and discuss your needs, visit their website or call their main office at (651) 270-0151.

About the Business

Have a question? Ask the experts!

Send your question