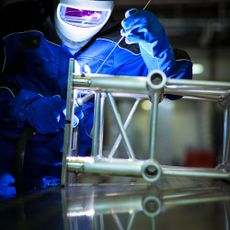

Inconel® is an extremely durable alloy, with corrosion- and heat-resistant qualities, which make it ideal for the most intense industrial applications. However, it’s also expensive and notoriously difficult to work with, even for the most experienced welders. To achieve the best results possible, there are a few things to think about before working with this advanced alloy.

What You Should Think About Before Welding Inconel

1. Purpose of the Part

While it’s always important to understand the function of the part you’re working on, knowing how the Inconel component will be used helps you figure out whether it can be improved. Inconel’s unique properties make it difficult to correct mistakes or make alterations later, so you may need to consult with the design team or machine manufacturer to learn more about how the part works and which qualities are most important.

While it’s always important to understand the function of the part you’re working on, knowing how the Inconel component will be used helps you figure out whether it can be improved. Inconel’s unique properties make it difficult to correct mistakes or make alterations later, so you may need to consult with the design team or machine manufacturer to learn more about how the part works and which qualities are most important.

2. How It’s Been Done Before

Before the part broke or wore out, did it work as expected? Were there any problems that can be corrected this time around? If the work of previous welders didn’t last as long as expected, the project gives you a chance to refine the process and produce a superior result.

3. How the Issues Get Corrected

Once you’ve identified any issues with the Inconel part, take the time to develop a strategy for improving them. Because this material is unforgiving, this task should only be handled by welders with extensive experience working with this expensive metal.

Whether you work with Inconel or need a new steel part fabricated, C & C Machine Inc. in La Crosse, WI, has the experience and inventory of materials to get every job completed efficiently. The expert welders have the training and specialized equipment to achieve the results you’re after on even the most difficult jobs. To speak with someone directly, call (608) 784-4427, or visit the website to discuss your metal fabrication project. You can also follow them on Twitter for more tips and advice.

About the Business

Have a question? Ask the experts!

Send your question