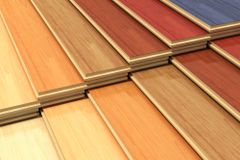

For many people, laminate flooring provides the beautiful elegance of hardwood flooring, but at a much more affordable price. Yet, the actual materials that make up this product are often mysterious to homeowners. Contrary to popular belief, this type of flooring is not entirely made of plastic—so what else goes into its manufacturing? To answer this question, the guide below highlights the different layers and components of this material.

The 4 Layers of Laminate Flooring

1. Wear

The top layer of laminate flooring is a transparent coating, which can typically be high gloss, matte, or something in between the two. This layer is made of aluminum oxide, protecting the floor against fading, stains, and burns.

2. Design

The design layer is what gives your floor its wood-like appearance. It is very thin and typically made from a high-resolution photograph of the wood species that the floor is mimicking. This layer provides the appearance of wood, but does not affect the floor’s durability.

The design layer is what gives your floor its wood-like appearance. It is very thin and typically made from a high-resolution photograph of the wood species that the floor is mimicking. This layer provides the appearance of wood, but does not affect the floor’s durability.

3. Core

The third layer of the floor is composed of resin, binders, and wood particles. As the thickest layer, the core is responsible for providing stability. The wood components come from leftover products, such as sawdust and wood chips.

4. Back

The bottom layer of this flooring is designed to provide additional stability and prevent moisture from rising into the laminate. It is typically made of melamine plastic and may be covered with an attached pad.

If you’re interested in installing laminate flooring in your home, the professionals at Thiemans Flooring, based in Wentzville, MO, will help. With more than 40 years of experience, this family-owned and -operated business prides themselves on long-standing partnerships and efficient service. Schedule a consultation with a flooring expert today by calling (636) 327-8813. Find more information about their services on their website.

About the Business

Have a question? Ask the experts!

Send your question