A Guide to Plasma Cutting

If you’re looking for a more efficient way to make occasional metal repairs or maintenance work, plasma cutting may be the answer. Like many industries, advancements in welding technology have allowed professionals to cut faster and produce more precise results, and plasma cutting is no exception. If you’re unfamiliar with the practice, consider the guide below.

What Is Plasma Cutting?

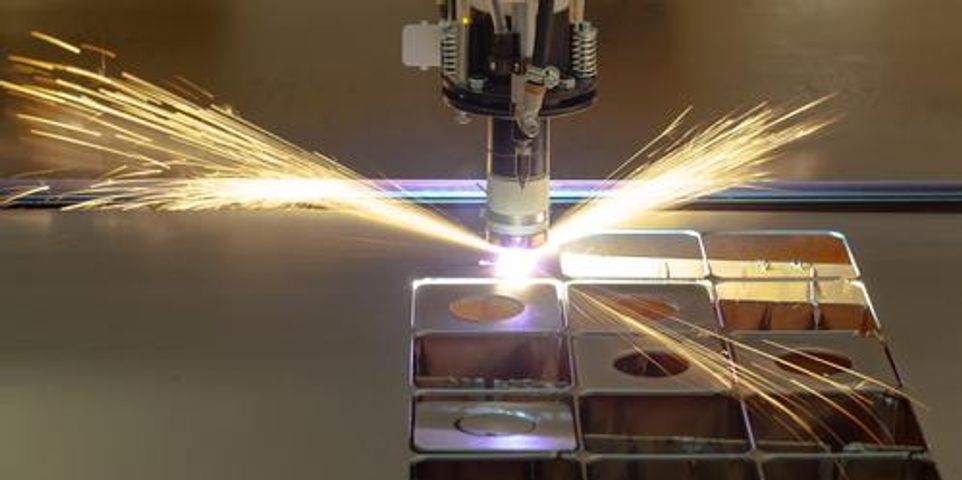

This method involves slicing steel and non-ferrous metal, but it boasts more efficiency than a mechanical saw. To operate, ionized gas is electrically charged and sent through a nozzle. This nozzle directs it like a laser to the uncut piece. The stream is quite dense and moves swiftly, which allows it to blow through most metals with relative ease. The result is a clean cut in almost any shape you desire.

This method involves slicing steel and non-ferrous metal, but it boasts more efficiency than a mechanical saw. To operate, ionized gas is electrically charged and sent through a nozzle. This nozzle directs it like a laser to the uncut piece. The stream is quite dense and moves swiftly, which allows it to blow through most metals with relative ease. The result is a clean cut in almost any shape you desire.

Why Is Plasma Cutting Important?

A mechanical saw has difficulty cutting non-linear shapes, which limits the capabilities of most welders. Because a plasma torch can cut rounded edges, it allows a skilled cutter to create any form, eradicating the previous limitations. A plasma torch is also much more portable than a mechanical saw, and far more efficient when cutting. The work can be completed faster because the tool heats the metal and blows it away rather than cutting through it.

If you need to slice a non-linear shape and would prefer a faster, more efficient alternative, plasma cutting is the way to go. This process will allow you to attain the rounded edges necessary to produce quality, intricate pieces.

Located in Waynesboro, WA, Wayne Oxygen & Welding Supply has been providing welding supplies to businesses throughout the region since 1959. Whether you need a new welding mask, compressed gas, or tools for an arc welding job, you can find all of the necessary items at their trusted shop. For more information on the products they supply, call (540) 942-4145 or visit their website.

About the Business

Have a question? Ask the experts!

Send your question