Everything You Need to Know About 3D Printing in Polyamide

3D printing, a major trend sweeping the tech field, is the process of making three-dimensional products from a digital file. While 3D objects can be made from a range of materials, polyamide is the one of the most popular due to its affordability and versatility. Serving residents throughout Rochester, NY, the experts at Faro Industries provide a wide range of top-quality services, including custom plastic, thermoforming, packaging, and 3D printing.

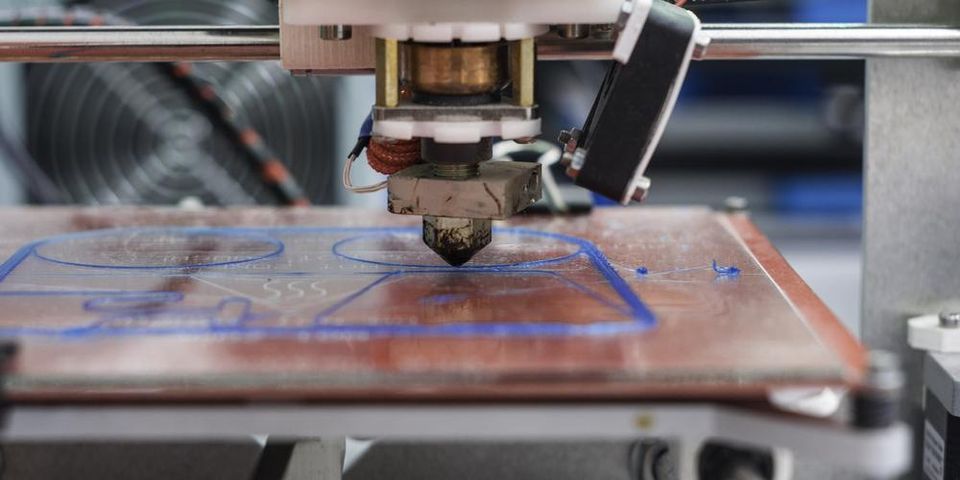

3D models can be created from polyamide, a white, powder-based medium with a melting point of 338 degrees Fahrenheit. This is important for creating the 3D print. First, a thin layer of polyamide is spread out by a roller and is then heated by a laser within the printer. It reaches a temperature a few degrees below the melting point, and then the areas of the design are heated to melt. This is conducted to sinter each layer of the design until the 3D object is created.

After the printing process is completed over a couple of days, the cooling phase begins. The object is too hot to touch immediately after the printing ends, which means an additional two days is required to allow the object to cool down. At the end of the cooling phase, the technician must dig out the sintered models contained within the block of powder.

After the printing process is completed over a couple of days, the cooling phase begins. The object is too hot to touch immediately after the printing ends, which means an additional two days is required to allow the object to cool down. At the end of the cooling phase, the technician must dig out the sintered models contained within the block of powder.

Once the sintered models have been removed, they are cleaned with vacuums and high-pressure air guns to remove any of the excess powder. The object is then coated with polishes or paints, depending on the request of the client.

If you’re looking for 3D printing for your project, you can count on the plastic professionals at Faro Industries in Rochester, NY. Call (585) 647-6000 to speak with a friendly representative, or visit their website for more information about their comprehensive list of services.

About the Business

Have a question? Ask the experts!

Send your question