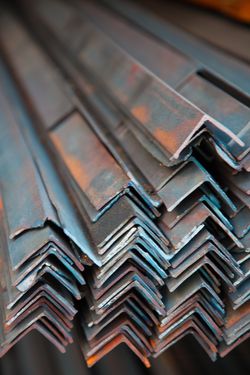

3 Ways to Prevent Steel from Corroding

Steel corrosion is a costly problem. According to IMPO magazine corroded machinery, buildings, and equipment cost the American metal industry an estimated $7 billion each year. Fortunately, there are simple things you can do to slow down and even prevent stainless steel corrosion. At American Metal Supply Co., the most trusted and respected metal supplier in the Cincinnati and Louisville areas, the steel distributors have more than 30 years of experience in the Industry

Corrosion costs — whether direct loss of metal structures due to corrosion, maintenance costs to control corrosion or explosions that are the result of corrosion — are a serious problem for the makers of buildings, bridges, boats, and other metal products. Dedicated to the customer, American Metal Supply Co. works tirelessly to help your business find greater success and profitability. Here are three tips from the metal processing experts at American Metal Supply Co. for how to prevent steel from corroding.

- Use Sacrificial Metals:

One of the best ways to protect steel is to coat the metal with a layer of zinc. The zinc, known as a sacrificial metal, will be exposed to the corroding elements and will protect the steel. Magnesium can also be used to protect steel from corrosion. Galvanic protection can work for decades.

One of the best ways to protect steel is to coat the metal with a layer of zinc. The zinc, known as a sacrificial metal, will be exposed to the corroding elements and will protect the steel. Magnesium can also be used to protect steel from corrosion. Galvanic protection can work for decades. - Apply Protective Coatings: Another way to prevent rusting is to coat the steel with a protective coating, such as paint, lacquer, or grease, that prevents exposure to oxygen, water, and salt. When using a passive barrier protection, look for coating systems with lower levels of permeability to water. For even more protection, look for primers that contain a reactive chemical compound that changes the surface properties of the steel, so it is less susceptible to corrosion.

- Install Impressed Current Cathodic Protection: When protecting pipelines, boat hulls, and storage tanks, this is the protection of choice because it requires considerable engineering and layout. Impressed current works by reproducing a current equal in strength to the corroding current but in the opposite direction. This system offers permanent and automatic protection against corrosion, but if used improperly and without the appropriate equipment and controls, it can promote corrosion.

Corrosion can be costly, but if you plan for regular maintenance to ensure protection from corrosion, you can minimize your costs and maximize your profits. For more information about how to prevent steel corrosion, call the steel distributors at American Metal Supply Co.

For more information about the leading provider of steel in Cincinnati and Louisville, visit the American Metal Supply Co. website or call the friendly and knowledgeable team at (502) 634-4321.

About the Business

Have a question? Ask the experts!

Send your question