3 Things to Keep in Mind When Choosing an Alloy Steel Grade from a Steel Supplier

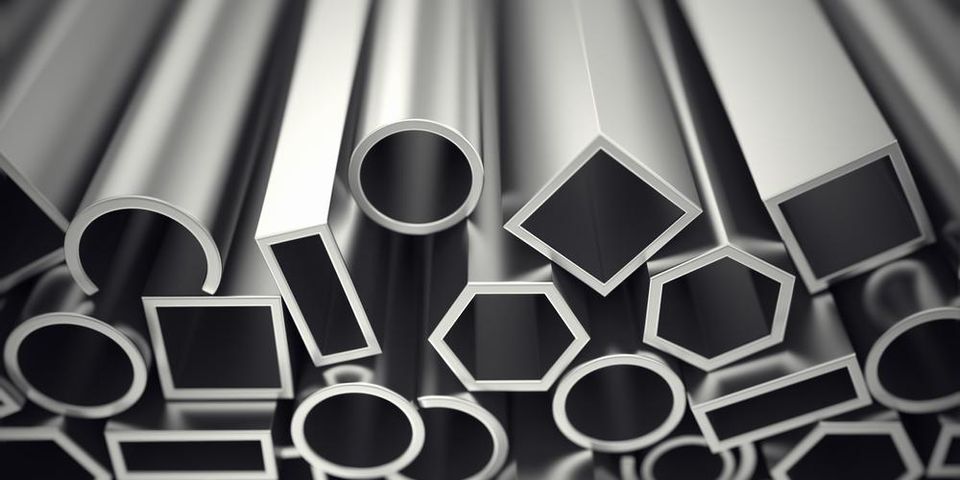

When faced with a project that requires alloy steel, it is imperative that you use a high-quality grade. This helps ensure durability, shine, and ease of use. To assist in the decision process, American Metal Supply Co. recommends keeping a few things in mind when purchasing from a steel supplier. With two convenient locations in Cincinnati, OH, and Louisville, KY, these experts have 20 years of experience helping countless satisfied customers.

Talk to your steel supplier about these three factors when deciding on an alloy steel grade:

-

Sulfur & Boron: Look for a grade that excludes the addition of sulfur or boron, especially if you are using the alloy steel in welding. When added, both can make your material susceptible to cracking. If salt levels exceed 0.05%, they can also create a brittle, dry element.

Sulfur & Boron: Look for a grade that excludes the addition of sulfur or boron, especially if you are using the alloy steel in welding. When added, both can make your material susceptible to cracking. If salt levels exceed 0.05%, they can also create a brittle, dry element. -

Corrosion Resistance: Corrosion is the deterioration of an element that occurs when the chemicals in the steel or metal react with their surroundings. Ask your steel supplier about additional corrosion resistance in your alloy steel. Grades that include chromium, copper, nickel, or molybdenum create a stronger defense against deterioration.

-

Strength: Depending on your project, you may require a high-level strength in your steel. Though it is already a powerful and durable substance, certain elements may be added in its creation process to increase its strength. The inclusion of manganese, chromium, iron, tungsten, and carbon helps improve resilience. Also, when steel is heated and then quickly cooled, the end result is a tougher element.

When purchasing from a steel supplier, always ask about how well the material welds, how well it resists corrosion, and its strength. For a metal supplier that guarantees top-quality materials, visit American Metal Supply. Whether you need stainless steel, aluminum sheet metal, or structural steel, their professional staff can handle it all. For more information, check out their website or call (502) 634-4321 today.

About the Business

Have a question? Ask the experts!

Send your question