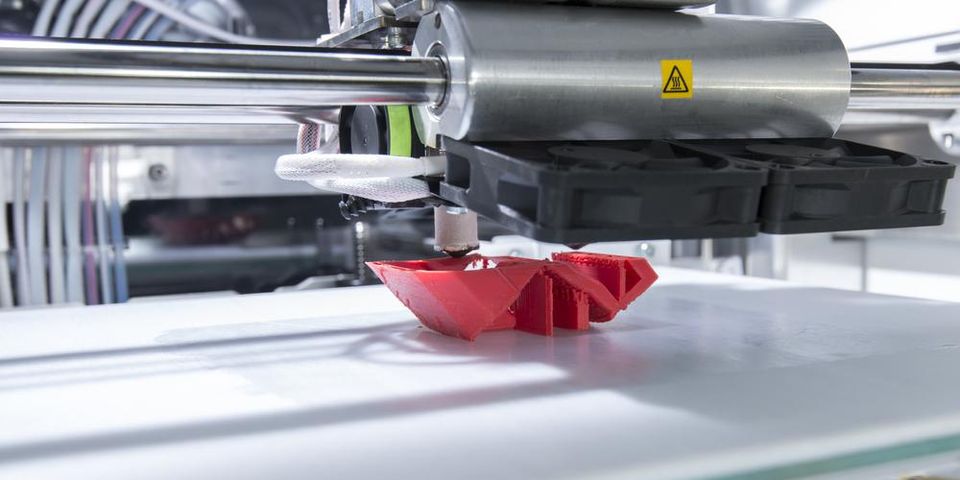

3 Tips for Obtaining the Perfect Wall Thickness With 3D Printing

Over the past few decades, 3D printing has been one of the biggest technological breakthroughs. It’s fast, cheap, and mitigates risk for companies seeking to fully visualize their products prior to actually making them. This technology is now more accessible than ever, but obtaining a useful result is still a tricky business, especially when it comes to wall thickness.

Rochester, New York’s Faro Industries has been a leader of technological design since 1967. Here, they offer three useful tips to obtain the perfect wall thickness with 3D printing:

- Design It Right: Design is essential for the 3D prototype you’re trying to print. Size and scale are vital factors in the quality of your print and will directly affect the maximum and minimum wall thicknesses you need. You’ll also want to limit physical design flaws like variations in structural density. The perfect wall thickness setting to support denser portions of your model may lead to structural weaknesses in lower-density areas.

Be Precise: Once you’ve settled on your design, you still need to do some math to figure out the right minimum and maximum wall thicknesses. Be precise in measuring the weight and dimensions of the object you want to print, and be specific about how much detail you want to see in your model. Wall thickness is a numbers game, and precise calculations are the only way to ensure your 3D print is successful.

Be Precise: Once you’ve settled on your design, you still need to do some math to figure out the right minimum and maximum wall thicknesses. Be precise in measuring the weight and dimensions of the object you want to print, and be specific about how much detail you want to see in your model. Wall thickness is a numbers game, and precise calculations are the only way to ensure your 3D print is successful.- Know the Material: Your design may be solid and your numbers sound, but wall thickness parameters shift dramatically between using plastics, metals, ceramics, or any other materials you might introduce to your 3D printing environment. So, you’ll need factor your printing materials into the mix before setting your wall thickness. Find out what materials require what parameters, then adjust your figures and design accordingly.

You can solve many of your wall thickness issues by choosing a versatile material like plastic for your 3D printing project, and nobody in the upstate NY area knows plastics better than Faro Industries. Call them today at (585) 647-6000 to talk to their friendly, experienced team about how their cutting-edge 3D printing technology can work for you. Or, visit them online to see their full range of services.

About the Business

Have a question? Ask the experts!

Send your question