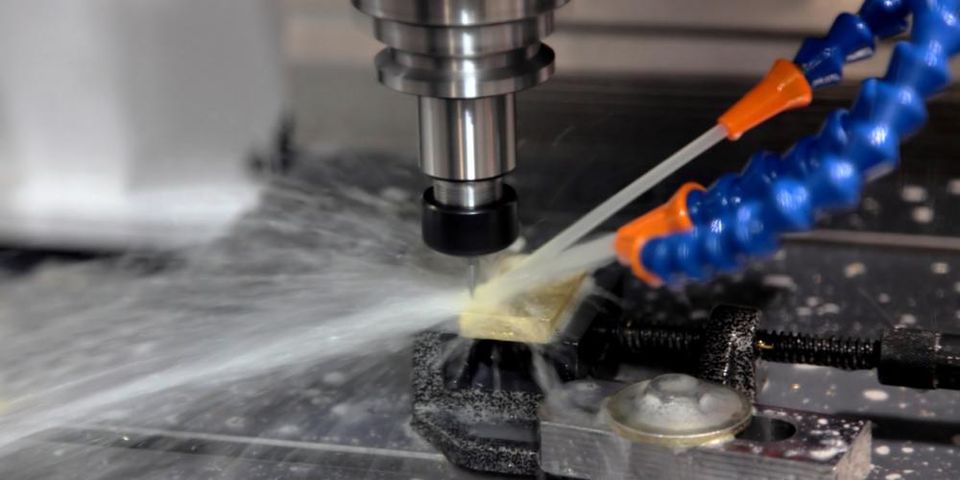

Whether you work with scrap metal or manufacture machine components, running a factory isn’t always easy, which is why C & C Machine in La Crosse, WI, specializes in machinery designed to increase efficiency and oversight, like their computer numerical control (CNC) machines. CNC machines have helped the manufacturing industry make excellent strides over the past decade, so C & C Machine has compiled a helpful list of a few of the benefits they offer.

If you want to improve your daily operations, here are five ways CNC machines have aided modern manufacturing:

- Accuracy: One of the leading benefits of CNC machines is that they can be programmed to create the thousands of identical products, making them more accurate than other types of machinery.

- Efficiency: Unlike other machines requiring on-site operators or occasional adjustments, once properly programmed, CNC machines can run nonstop and only need to be turned off when they’re in need of immediate maintenance.

Updates: Since CNC machines utilize computer technology, they can be updated on a regular basis with cutting-edge software to improve efficiency and correct any errors.

Updates: Since CNC machines utilize computer technology, they can be updated on a regular basis with cutting-edge software to improve efficiency and correct any errors.- Volume: Because CNC machinery can reproduce thousands of identical copies without error, it’s ideal for high-volume production purposes, allowing manufacturers to minimize mistakes and offer high-quality products at more affordable prices.

- Supervision: Another benefit to utilizing CNC machinery in the workplace is it requires little monitoring, meaning that once it’s programmed, they can be left to run on their own, helping your save on labor costs.

If you’re looking for high-quality metals at affordable prices, you need a reliable metal manufacturer; contact the metal fabrication professionals from C & C Machine at (608) 784-4427. They’re also equipped to perform machine repairs, so send them a message here to receive a quote.

About the Business

Have a question? Ask the experts!

Send your question