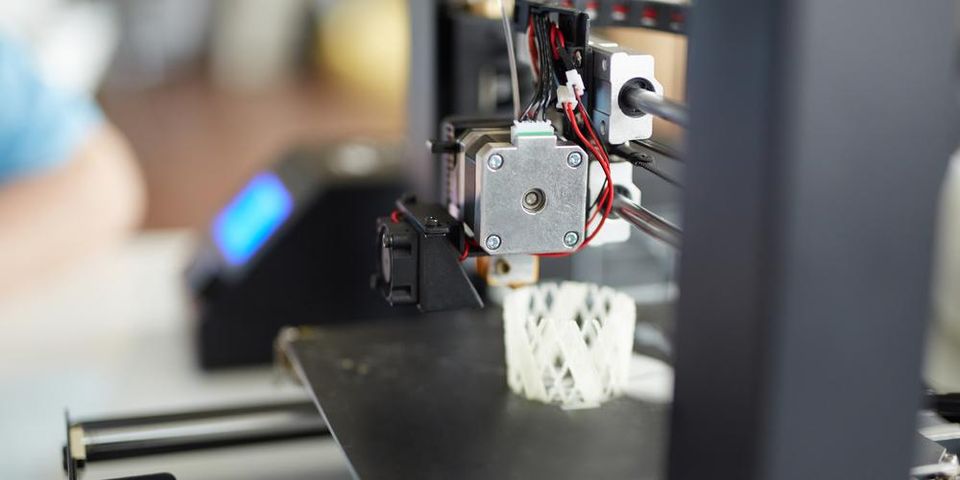

3D Printing: Avoid These 3 Mistakes When Designing a Model

3D printing is no longer the stuff of science fiction movies. Today, it’s being used by a growing number of individuals and industries to create a wide range of objects for different purposes. However, while the technology is becoming increasingly user-friendly, there are still some common pitfalls that you can easily avoid by following the three steps outlined below:

1. Understand the Material You Are Using

The design is, to a large extent, dependent on material, and considerations, such as hardness and flexibility, will dictate what types of objects or structures you can print successfully. It’s important that you understand the properties of the material you are planning on using to make sure it’s appropriate for your project. If you don’t, you may find your final product is not structurally sound.

2. Choose the Proper Software

Not all 3D printing software is created equal, and the one you should choose will vary depending on what you are looking to print. For example, artists can use programs specifically designed for printing sculptures, while architects might use one that allows them to print sketches of the design.

Not all 3D printing software is created equal, and the one you should choose will vary depending on what you are looking to print. For example, artists can use programs specifically designed for printing sculptures, while architects might use one that allows them to print sketches of the design.

3. Consider the Different Kinds of Printing Technology

A structure comprised of many different materials may require the 3D printer to do different types of printing. However, these types of projects can often result in design limitations. It’s important that you understand the printing technology required for your project, so you can ensure the compatibility of all the features in your design.

Are you looking for help with a 3D printing project? Faro Industries in Rochester, NY, has the technology you need to design and produce your object. You can learn more about their services on their website or call them at (585) 647-6000.

About the Business

Have a question? Ask the experts!

Send your question