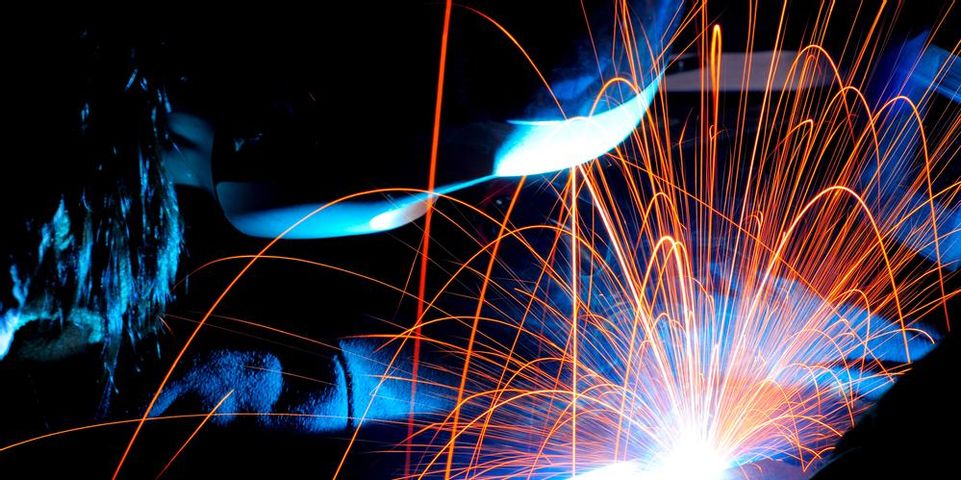

Whether you need your pontoon boat repaired or you want to build a custom-made gate, a professional welding company has the expertise to complete your project. Before you choose a company to work with, it's a good idea to familiarize yourself with the different types of welding so you know which questions to ask your welder. Here, the commercial welding experts at Brady's Welding Specialties, located in Tacoma, WA, discuss the most often-utilized types of welding.

These are three of the most commonly used types of welding:

- MIG Welding: MIG, or gas metal arc welding, uses electricity to melt and secure pieces of metal together. It is considered one of the easiest types of welding to learn and can be used to weld carbon steel, aluminum, and other alloys. This type of welding uses an arc of electricity to create a short circuit between the wire-fed welding gun and the metal being welded.

- TIG Welding: TIG, or Tungsten Inert Gas welding uses an arc of electricity that travels from an electrode to a metal welding surface, generating heat and producing a high-quality weld. It can be used to weld copper, aluminum, or titanium and is a useful type of welding for difficult projects, such as welds on round shapes.

Arc Welding: Shielded Metal Arc welding joins two pieces of metal using a flux-covered electrode. The metal between the two pieces melts when intense heat from an electric arc is applied, creating a strong bond between the two metals. Arc welding is useful for a variety of applications and is a cost-effective type of welding.

Arc Welding: Shielded Metal Arc welding joins two pieces of metal using a flux-covered electrode. The metal between the two pieces melts when intense heat from an electric arc is applied, creating a strong bond between the two metals. Arc welding is useful for a variety of applications and is a cost-effective type of welding.

The commercial welding experts at Brady's Welding Specialties perform on-site metal repairs, specializing in aluminum, magnesium, and stainless steel. Give their team a call at (253) 475-4608 or visit them online to learn more about their mobile welding services.

About the Business

Have a question? Ask the experts!

Send your question