Rochester's Faro Industries Gives You a Look at the Machines Used in Professional Plastic Printing

Nowadays, with the advances in 3D printing technology, molding, and thermoforming, printers are able to design and render plastic products that can be created with unparalleled accuracy. At Faro Industries in Rochester, NY, the team offers a wide range of professional plastic printing and manufacturing options. Whether you want to manufacture food containers or medical components, they’re equipped to create it all. They'd like to give you a closer look at the machines they use:

- Thermoforming: Faro Industries employs several different stations with thermoforming machines designed to manufacture an extensive range of professional plastic products of nearly any shape and size. These machines heat the plastic, allowing it to be molded or pressed into nearly any form, and then trimmed or pulled into shape. These products are then vacuum formed to create the finished plastic product.

- Machining: For the manufacture of non-plastic parts, or when working with certain molds, Faro Industries employs the use of several CNC machines. These machines utilize tools that can be easily programmed to perform a range of functions, including shaping, lathing, milling, and more. Faro Industries also has three standard vertical milling machines.

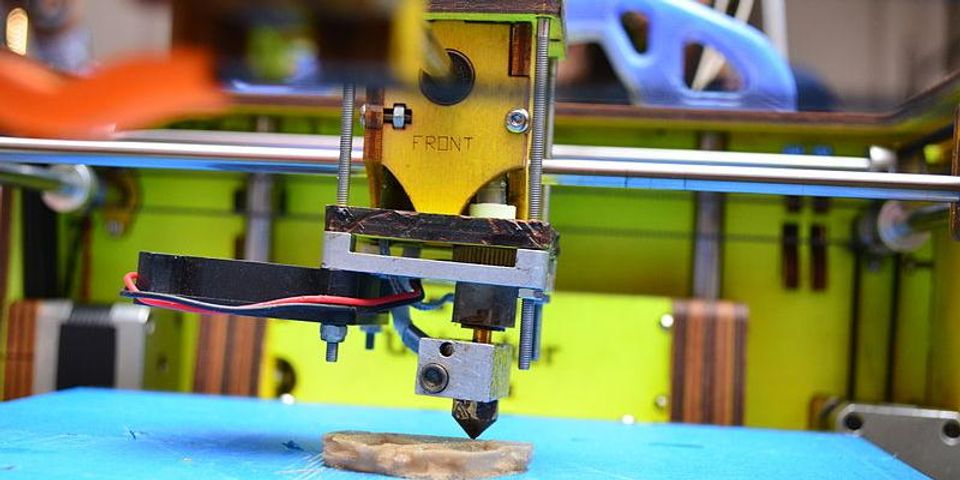

- 3D Printing: For rapid plastic production, Faro Industries uses a 3D printer to create prototypes with three different kinds of plastics: ABS (acrylonitrile butadiene styrene), polycarbonate, and ultem. This machine uses a fused deposition modeling technique that is actually quite simple, and lays down the plastic in layers. Those interested in creating a short run of professional plastic products extremely quickly will benefit from 3D printing.

To learn more about the 3D printers and other plastic manufacturing machinery employed by Faro Industries, contact them today at (585) 647-6000, or visit them online for an extensive list of services.

About the Business

BUSINESS

Plastic Product Manufacturer

Faro Industries, Inc.

340 Lyell Ave, Rochester, NY 14606

Have a question? Ask the experts!

Send your question